A Comprehensive Comparison of Tin vs Aluminum for Your Business

Waqas Khan Pitafi 2025-03-12 09:19:00

Metal packaging has become crucial in various industries for the past few years. The durability and versatility of metal make it ideal packaging material for preservation, protection, and transportation. The global metal packaging market is expected to grow from $150.59 billion in 2024 to $194.68 billion by 2032, at a CAGR of 3.26%.

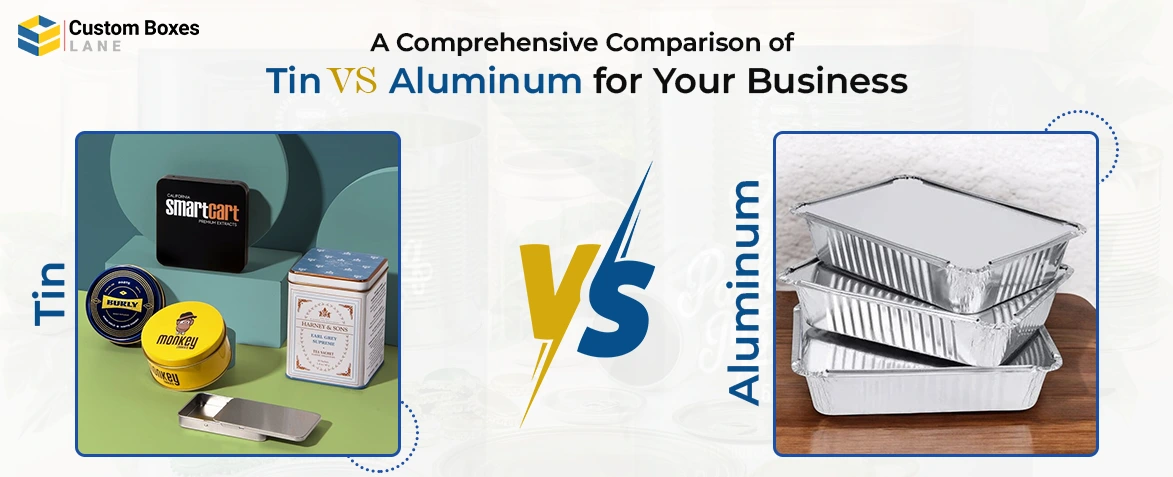

In the packaging industry, two metal packaging types are common: tin and aluminum. However, which one should businesses choose for their products becomes questionable. Because each metal type serves a unique purpose due to its varied properties.

This blog explores aluminum vs tin packaging in detail and guides you to decide which one you should choose to maximize brand visibility and profitability.

Tin Packaging

Tin packaging is also known as tinplate packaging. This packaging has thin sheets of steel coated with tin. The layering of tin prevents steel from rusting owing to its corrosion resistance. This feature ensures food remains uncontaminated.

Tin packaging is popular for packaging canned foods, soups, vegetables, pickles, and meats. Due to their barrier properties against light, moisture, and oxygen, tin cans are an ideal choice for packing food items. Because light, moisture, and oxygen degrade the quality of food items.

But tin packaging has its own pros and cons. Have a look at them to have a better idea of their suitability for the packaging of your product:

Pros of Tin Packaging

- Durable: Tin packaging is sturdy. It absorbs shocks and vibrations during shipping, making secure delivery of products like spices at retail shelves or customers’ doorsteps.

- Corrosion-Resistant: Tin is an ideal packaging material to protect food, retaining its flavor, natural oils, and aroma. Tin prevents environmental deterioration and preserves food for a long time.

- Protection: Tin packaging comes with airtight seals and solid containers, which prevents light, oxygen, and moisture entry. This prevention is to prevent food from going stale and contaminated.

- Eco-friendly: Tin can be recycled easily. Hence, it supports environmental sustainability. Also, customers reuse tin cans for preserving homemade goods, organizing jewelry and other items.

Cons of Tin Packaging

- Costly: As tin is a recyclable material. But recyclability takes a lot of energy and resources to recycle tin cans or bottles, which reduces costs.

- Heavyweight: Tin is a relatively heavier metal item than other types. Due to its heavier weight, shipping costs also increased.

- Limited Availability: Tin is not a readily available metal as compared to aluminum.Low availability of this metal raises its price.

Aluminum Packaging

Aluminum packaging is lightweight, versatile, and eco-friendly. Aluminum foil is used in this packaging process. Due to the non-toxic nature and corrosion-resistant nature of aluminum foil, this packaging becomes an ideal choice for the food, beverages and pharmaceutical industry.

The distinctive feature of aluminum is the cooling ability of foil, which allows storage of perishable products without a refrigerator. Aluminum foil also offers high resistance against moisture, light, heat, and oxygen to preserve freshness and quality of the inside packed products.

Like tin packaging, aluminum packaging also brings pros and cons. Dive deep into it to know whether aluminum will be a suitable choice for your product or not:

Pros of Aluminum Packaging

- Durable: Aluminum is a robust metal with high strength which ensures the integrity of products. This durability prevents leakages, contamination, or physical damage of these products.

- User-friendly: Although aluminum is durable, it is also lightweight, which makes it easy to handle and carry from the production center to retail shelves.

- Non-Toxic: Aluminum foil does not react with the inside contents due to corrosion-resistance. That is why the taste, or the flavor of food items does not change.

- Budget-Friendly: Due to lightweight aluminum packaging, it reduces the transportation costs. Its abundant availability also makes this packaging cost-effective compared to tin packaging.

Cons of Aluminum Packaging

- Soil and Water Contamination: If aluminum foil waste is not managed properly, it contaminates soil and water. Aluminum particles affect both aquatic and plant life after their leaching.

- Non-eco-friendly: The production of aluminum takes a very high amount of energy. This contributes to greenhouse gas emissions, which negatively impacts the environment.

- Non-flexibility: Aluminum is somewhat not so flexible in terms of design. It is a bit difficult to customize aluminum in any desired shape or style, comparatively to tin.

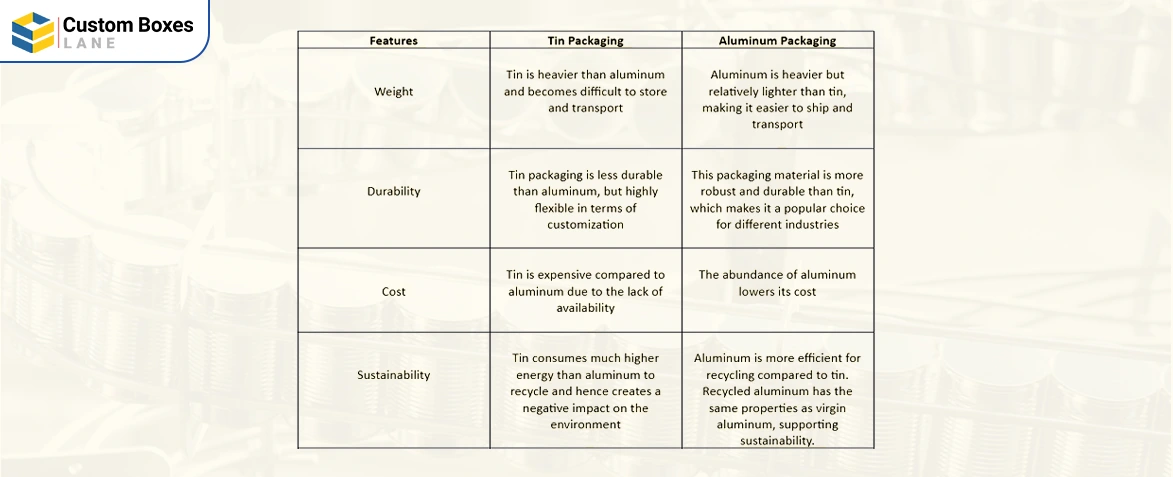

Main Differences Between Tin and Aluminum Packaging

Although tin and aluminum have many similar properties, there are some major differences between them. Let’s explore them:

Uses of Tin in Packaging Industry

Tin packaging has multiple applications in diverse industries, serving unique purposes. Explore them:

- Food cans and tins: Airtight sealing, preservation, light-proofing, firmness and unique metal decoration charm of tin make it an ideal choice for packaging food items.

- Beverage cans: Preserve taste, texture, and color of beverages for a long time. Beverages and other types of drinks don’t spill or leak inside the tin cans.

- Paint cans: Corrosion-resistance of tin keeps paint safe for a long period by preventing rusting of steel. Also, paint doesn’t leak with the airtight seal of tin.

- Aerosol cans: Designed to provide ample space to hold a large amount of air freshener while remaining compact and convenient for daily use.

- Cosmetic tins: Tin offers an old-school charm and is great for cosmetic packaging because it's strong and protects cosmetic products without compromising quality.

Uses of Aluminum in Packaging Industry

Aluminum cans and bottles have diverse applications across different industries. Let’s dive into that:

- Food Industry: Aluminum foil with barrier properties preserves the freshness of food items such as meat, vegetables, and cheese for a long time despite harsh environmental conditions. For example, oven safe packaging utilizes aluminum to keep foods safe.

- Pharmaceutical Industry: Blister packs with aluminum foiling protect medicines and injections from excessive heat, moisture, and light.

- Cosmetic Industry: Aluminum bottles and jars stand out in the market for preserving aroma, texture, color, and quality of lotions, creams, perfumes and other cosmetic products.

- Personal Care Products: Aluminum packaging tubes are ideal for packaging toothpastes, jams, deodorants, hair products and other daily care products

- Pet Industry: Aluminum packaging tubes are also used for pet care due to distinctive features, such as good shading, moisture-proof, airtight, corrosion resistance, non-toxic and tasteless nature.

Tin vs Aluminum: Which One Should You Choose?

When it comes to deciding whether your business should opt for tin or aluminum packaging, there are several factors to consider. You may weigh out both metal types based on their characteristics, comparative overview, and industrial use depending on your business needs.

If your concern is to go for cost-effective and durable packaging, then aluminum packaging is a suitable option. But if you want to go for a visually appealing but expensive packaging solution, tin cans serve best to impress customers.

In case you want a premium packaging solution for your tin or aluminum cans, jars, or bottles, contact us and witness an elevated brand experience.