A Guide to Measure Dimensions of Box Packaging

2024-12-17 06:17:06

Measuring box dimensions is effortless but requires careful consideration to ensure the box offers a snug fit for the product. Understanding box dimensions order helps you correctly measure packaging and shipping boxes to ensure product safety. The correct box dimensions directly impact your production, shipping, and storage costs.

This is why measuring boxes with the dimensions that align with the product dimensions order helps you get cost-effective packaging. Take the inside and outside dimensions of box for perfectly customized packaging. Read this blog to learn how to measure the dimensions of box packaging correctly!

What Order are Dimensions of the Box?

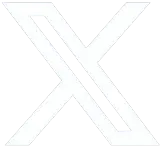

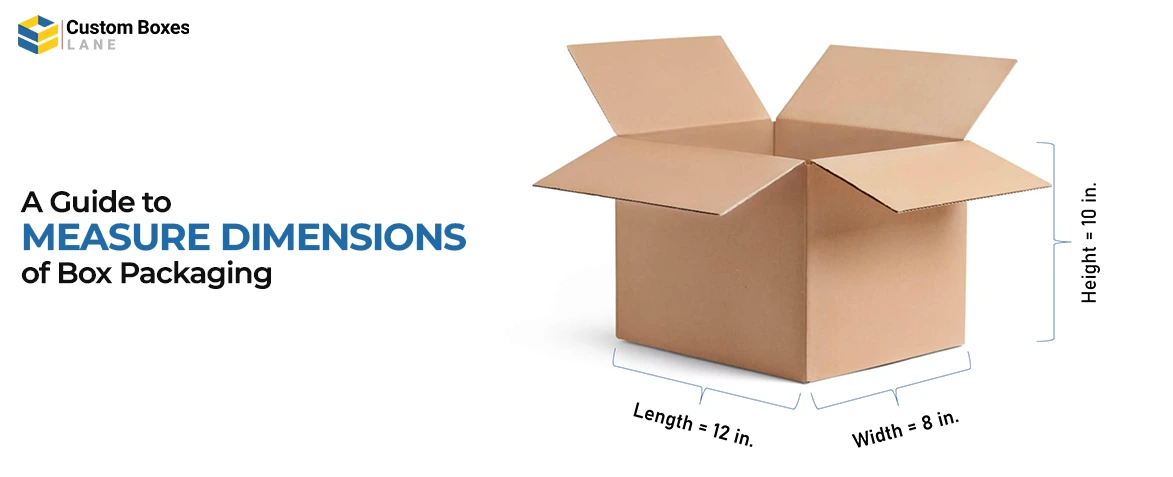

The standard dimension order is length x width x depth (LxWxD) for measuring shipping and retail product boxes. Sometimes, it refers to length x width x height (LxWxH). Length is the longest side of a box. Width is the shortest side of a box and perpendicular to the longest side. Depth is the top-to-bottom vertical side of a box. It also refers to the height of a box. It is perpendicular to both the length and width of the box. Box dimensions height width depth order help you design packaging that ensures a snug fit for your products.

Things You Need For Measuring Box Dimensions

You need to follow the standard measurement order to know the correct dimensions. Some measuring essentials are required to measure the dimensions of box packaging. Before you dive into how to measure the dimensions, get the following essential tools:

- Ruler for small box packaging.

- Pointer for marking if needed.

- Measuring Tape for accurate measurement.

- A Yardstick for measuring large boxes.

How to Measure the Dimensions of Box

Follow the order of measurement dimensions step by step mentioned as follows:

Measure the Length of the Box

Start by measuring the longest side of the box first with a ruler and measuring tape. Use a ruler to measure the dimensions of a small mailer box or product box. Otherwise, a yardstick will be helpful. The longest side usually has flaps that tuck inside to ensure secure closure. Decide the unit for noting the measurements. Taking the dimensions of a box in inches is easier. Place the ruler from one end of the box to the other and note the length.

Measure the Width of the Box

Now turn the box to a 90° angle to measure the width. This side of the box also contains flaps but these flaps are shorter than the flaps on the longest side. Place the measuring tape from its top to bottom end and note the reading.

Measure the Depth/Height of the Box

Don’t get confused with Depth and Height. They are the same. In simple terms, height or depth refers to how tall a box is. Keep the box opening face in front of you and close the flaps securely before measuring the height or depth. Now place the measuring tape from top to bottom and write the readings.

Calculate the Box Volume

Now calculate the volume of the box after taking the three dimensions. Let’s take an example of the dimensions of a standard shipping box, which is 16” in length, 12” in width, and 12’ in depth/height. The following formula will be applied to calculate the volume of a box:

Volume = Length x Width x Height

Volume = 16 x 12 x 12

The volume of a standard shipping box will be 2,304 cubic inches.

Take the Internal Dimensions of Box Packaging

One of the significant considerations in measuring a box is internal box dimensions, especially for corrugated shipping boxes. Corrugated material contains multiple layers of cardstock and kraft flutes, which means the inside box dimensions will differ due to higher material thickness. About every product-based industry depends on corrugated boxes for shipping products.

Therefore, the market for corrugated boxes is expected to grow between 2023 to 2027. Inaccurate box dimensions can lead to delayed shipping, damaged products, poor customer experience, and higher shipping costs. However, some companies clearly distinguish between the external and internal dimensions of box packaging to make the manufacturing and shipping processes easier.

4 Careful Considerations for Perfectly Customized Box

Whether you want to create a shipping or retail product box, the following considerations help you measure the box with accuracy:

- Understand your products’ nature and dimensions and choose the packaging material accordingly. Then, measure the box’s internal and external dimensions to provide a snug fit to the product.

- Comply with regulatory requirements because some shipping companies do not accept products packed in incorrectly measured product boxes. This can also lead to higher shipping costs. Carrier companies’ special dimensional weight restrictions can disturb your supply chain management.

- Determine customers’ contemporary preferences and focus on user-friendly box sizes for particular products. Boxes with less thickness will have fewer internal and external dimensional differences. Likewise, boxes made from thicker materials have different internal and external dimensions.

- The boxes with inserts should be measured according to the huge difference between their internal and external dimensions to ensure product safety. Understanding how to read product dimensions can help you measure the box's internal dimensions.

Conclusion!

Measuring the dimensions of box packaging is not rocket science yet careful considerations are needed such as understanding the standard dimension order and getting the right essential tools. Likewise, taking the inside and outside dimensions of box packaging according to the type of your products is crucial. Length, width, and height are three dimensions that help you get accurate measurements and box volume.

Still, have questions? Feel free to contact us! We would be happy to assist you!