Everything You Need to Know About Aqueous Coating!

Waqas Khan Pitafi 2026-02-27 16:00:00

Customization is what helps a brand in getting a distinctive look when displayed on the shelf. Finishes are a part of customization and offer a variety of options including aqueous coating. Most brands prioritize using aqueous coating on their packaging boxes to beautify these boxes.

If you are looking for ways to attract customers and stand apart from the competition, give this coating a try. Coating adds a final layer of beauty to several items such as packaging boxes, brochures, envelopes, and more. Read this blog till the end to find out important details about this coating and when you should use it.

What is Aqueous Coating?

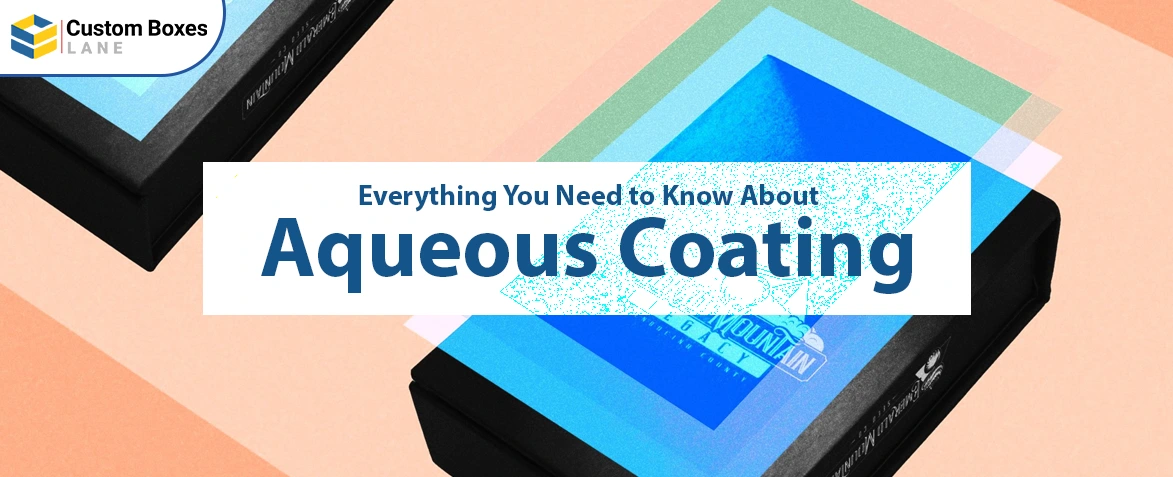

Aqueous coating, also known as AQ coating, is a water-based coating applied to sheets to give an elegant appearance. With the attempts to be more sustainable, brands are moving towards this coating as it is a biodegradable coating. Try AQ coating on your packaging boxes as it pops out the colors and attracts more customers.

AQ coating is also known as flood coating as it covers the entire surface and not just s few spots. In comparison to others such as UV varnish, AQ coating is less likely to turn yellow, thus offering an evergreen elegance. Moreover, this coating is more flexible than UV coating and cannot be cracked easily.

Why Choose Aqueous Coating?

Now that you know what is AQ coating, it’s time to know the benefits of this finishing type. This coating offers a lot of advantages which is the reason more and more brands use it on their boxes. Here are three important benefits this coating has to offer:

-

It is a Budget-Friendly Option

Do you know that your packaging can outshine within a limited budget? Aqueous coating is a budget-friendly option that can help your brand in saving costs. Give your packaging boxes a beautiful shine with this affordable option and stand out in the market.

-

You Can Reduce Your Carbon Footprint

AQ coating is a water-based coating applied to surfaces for a beautiful look, which makes it a sustainable option. This means that using this coating allows brands to reduce their carbon footprint. You can attract eco-conscious customers by using this coating.

-

It Keeps the Surface Protected

Are you printing business cards or are your products going into retail? It is a wise choice to use an aqueous coating when the boxes will be touched by multiple people. This is done to avoid the fingerprint smudges and abrasions that may be caused during shelving.

Different Types of Aqueous Coating

Aqueous coating has a variety that offers a distinctive yet elegant look. You can choose the type based on your brand’s need or product demand. Retail packaging should be treated differently than others as it’s a place where several brands are competing against one another. Here are 6 types of aqueous coating you should try for your packaging boxes:

-

Matte Coating

The matte aqueous coating gives a beautiful muted look to the surface and offers minimal shine. However, this finish gives a high color intensity to attract customers.

-

Gloss Coating

You can try gloss aqueous coating if you want your boxes to have a reflective surface when displayed on shelves. It gives a bit more shine than a matte coating.

-

Dry-Erase Coating

If you want to give your packaging a similar look as lamination, this coating is for you. Dry-erase coating offers a glossier effect to attract customers.

-

Pencil Coating

This coating is a type of matte coating that allows the use of ink pens, pencils, and lasers to give an impeccable and smooth look.

-

Soft Touch Coating

The Soft-touch coating offers a smooth velvet-like texture under the touch in addition to the matte-like appearance.

-

Satin Coating

The satin coating offers less sheen than a gloss coating but more protection against abrasions, and fingerprint smudges.

When Should Aqueous Coating Be Preferred?

While there can be many reasons to choose aqueous coating, there’s one important reason why it is preferred by the food industry. This coating is non-toxic and does not release any chemical toxins when applied on the surface. This makes it a very good choice for use on food boxes such as cereals, juice boxes and pouches, milk cartons, etc.

Which Products to Use Aqueous Coating on?

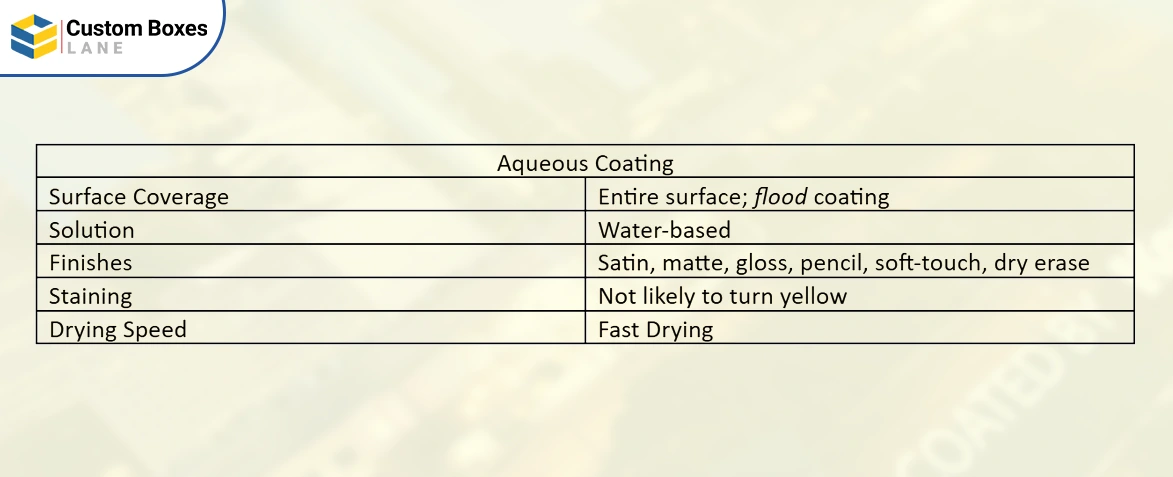

When it comes to AQ costing, it is not a daunting task to decide when and how you should be using it. For most brands, the primary reason for choosing AQ coating is to avoid fingerprint smudges and abrasions.

This is the reason it is always encouraged to use this coating on products that are to be picked up by multiple people. Here is a list of products that you can use AQ coating on to keep these items as good as new until they reach the customers:

- Business Cards

- Greeting Cards

- Flyers

- Booklets

- Envelopes

Which Products to Not Use Aqueous Coating on?

With advantages come certain disadvantages and you must keep that in mind before finalizing your decision about going with this coating. This coating needs a smooth application for it to attract more customers. This is why using it on low-quality papers will make the surface blotchy and will give an inconsistent look.

Certain packaging boxes with chemicals should not have an aqueous coating as the chemicals can cause disruptions. The chemicals will make it challenging for the coating to stay on the boxes. Here are a few products not compatible with AQ coating:

- High-Absorbent Paper

- Low-quality Paper

- Essential oil Packaging

- Perfume Packaging

- Cosmetic Packaging

Enhance Your Packaging’s Appearance with AQ Coating!

Aqueous coating will allow your packaging boxes to have a distinctive yet elegant look. Consider this coating to stand apart from the competition in the market. As a brand, you can also reduce your carbon footprint by choosing this environmentally-friendly coating. Contact Custom Boxes Lane today to get a free personalized quote regarding custom packaging. Give your boxes a visually appealing look with this exquisite coating.