Gloss Vs Matte Pizza Boxes: Which One to Choose?

2025-02-03 10:52:50

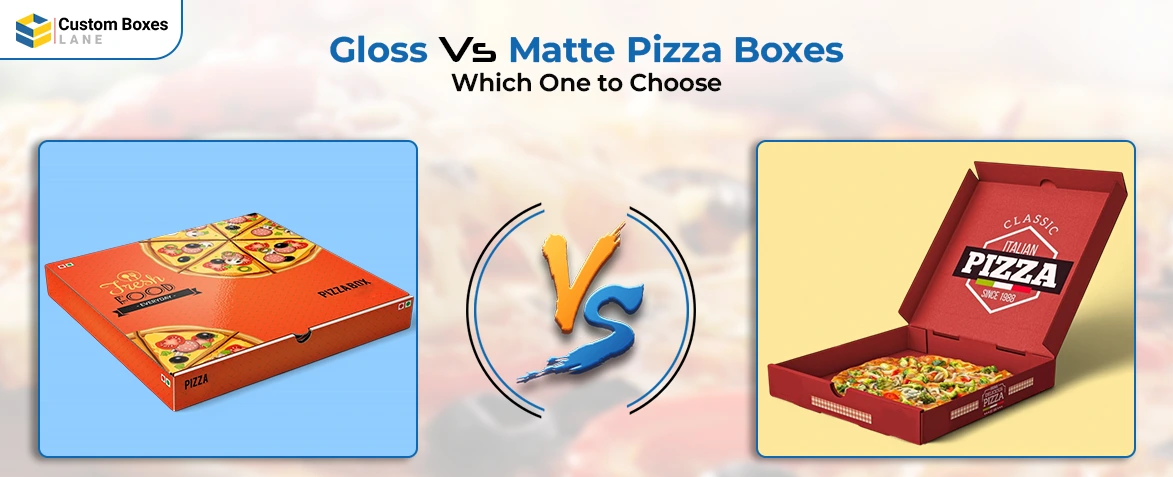

Adding a fine touch of elegance can enhance the visual appeal of your product packaging by many folds. To do so, choosing an appropriate finish for the boxes is paramount. If you are a pizza-selling business looking for appropriate packaging lamination of coating, this guide is for you.

In this blog, we will explore a comparison between gloss and matte laminations (two of the most popular finishing choices). Read on to decide which type of finishing will align more with your pizza brand!

Importance of Finishing for Pizza Boxes

Finishing plays an important role in enhancing the looks and protective properties of your pizza boxes. When it comes to protective features, the finishing you choose can add to the strength and durability of box materials. Also, these finishes are mostly waterproof which helps keep pizzas packed in them fresh.

Choosing an appropriate finishing can also help you enhance the captivity of your boxes for pizza packaging. For instance, gloss finishes get the attention of your customers and glorify your brand logo. If you go for matte finishing, buyers enjoy a subtle and high-end feel that enhances the perceived value of your pizzas.

The importance of finishing can’t be overlooked in protecting the printed graphics. Whether you go for lamination or coating, it acts as a barrier between printed graphics and environmental factors. That’s how finishes retain the captivity of prints on pizza slice boxes for a long time.

Difference Between Coating & Lamination

Before we dive into the comparison between matte and gloss finishing, let’s discuss the difference between coating & lamination. Both coating and laminations are similar due to their identical benefits. However, both are primarily two different finishing approaches.

In coating, a varnish or other liquid substance is applied to the boxes. This substance, whether gloss or soft-touch, is cured with ultraviolet lights. The liquid ultimately solidifies and gives you a finished packaging. On the other hand, lamination is a sheet of plastic or any other material that is pasted on the surface of the box.

When it comes to pizza boxes, you can pick any finishing option of your choice. The reason is that both coating and lamination are fully supported by the pizza box materials.

Gloss Lamination

A captivating lamination of coating famous for its shiny appearance is gloss lamination. This type of lamination and coating is widely used to protect and enhance the visibility of various retail boxes. Highly polished plastic films are mostly used to create gloss lamination, and aqueous varnish is used as gloss coating.

Pros

- The glossy look enhances the visual appeal of custom boxes

- Enhance the visibility of vibrant colors and attract the target audience

- Water-resistant features of gloss finishes enhance the shelf-life of boxes and products packed inside.

Cons

- Scratches and fingerprints are more visible on gloss lamination.

- Dust & dirt create a more poor look as it’s visible on gloss finishes.

- Sometimes the glare of these finishes makes it difficult for prospects to read the text on the boxes.

Matte Lamination

A premium and luxurious feel can be incorporated into your packaging boxes with subtle matte finishing or lamination. Like gloss lamination, matte one is also made of plastic, yet less polished. Matte coating substances are water-resistant varnishes having lesser reflective properties.

Pros

- Enhance the perceived value of boxes and products packed inside.

- The soft touch of matte lamination offers a timeless tactile experience to customers.

Cons

- Develop smudges & marks over the time.

- Matte finishes are a bit more costly and complicated to be applied than gloss ones.

Comparison Between Matte & Gloss Lamination

If you want to find which type of finishing between matte vs gloss is more suitable for your pizza boxes, comparing the properties of both is essential. Here is a detailed comparison of the two most famous finishes:

Which One is Best?

After knowing all the features, pros, and cons of matte and gloss laminations, it’s time to decide which one to choose for your pizza boxes. It depends! If you want to create an exciting experience and want your customers to pay more attention to your brand logo, opt for gloss laminations.

However, if you want to persuade your buyers with the premium feel of your boxes, go for matte lamination. Using matte lamination, you can also enhance the perceived value of your pizzas helping you sell your products at a premium.

Where to Customize Finishing for Pizza Boxes?

Customizing finishes from a reputable service provider is essential to get outclass results. You can opt for an online packaging company like Custom Boxes Lane to customize the finishing of your pizza box packaging.

With free design support and complete guidance on finishing, we can create timeless boxes for your pizzas. With our durable and elegant pizza boxes, you can be sure that your pizzas remain fresh and that your customers love them at first sight.

Conclusion

Choosing a timeless finishing option for your pizza boxes can uplift your packaging game. We hope this guide on gloss vs matte pizza boxes will help you make an informed decision about finishing your branded boxes for pizzas. If you need further assistance or want to customize your pizza boxes, get in touch with us!