Know Everything About Mylar Bags! A Comprehensive Review

Waqas Khan Pitafi 2025-10-07 09:53:27

One of the extensively used packaging across major industries for products’ longevity is custom Mylar Bags. These bags are primarily made from PET, a flexible film that has excellent barrier properties. PET is molded into various shapes to form Mylar bags, ensuring the superior protection of products against moisture, air, light, and oxidation.

The irresistible benefits of custom Mylar bags depict a bright future for market growth. However, the market is still facing a few problems, like the environmental impact of Mylar bags.

Businesses selling perishable products must invest in Mylar bag packaging. Let’s delve into a comprehensive review of custom Mylar bags!

What Are Mylar Bags?

Before analyzing Mylar bag packaging deeply, understanding what they are is essential. Custom Mylar bags are flexible packaging used for packing a variety of different perishable and non-perishable products.

You might have seen food items like snacks, nuts, chips, candies, and gummies packed in thin, flexible packets; they are custom Mylar bags. What makes Mylar bag packaging unique is its great barrier properties that ensure the product protection from oxidation, air, moisture, and light.

A question that might be triggering in your mind right now is,” What material is used for creating Mylar bags?” The answer is that the barrier properties of Mylar bags are from the primary material used for making them, which is PET (polyethylene terephthalate).

PET is a flexible and stretchable film with excellent barrier properties. It is used for creating different shapes, styles, and sizes of Mylar bags. Not only is PET used in bagged form for protecting products, but Mylar sheets are also used for protecting products from moisture and air.

Your next question might be,” What are Mylar sheets?”. Mylar sheets are thin and flexible, made from biaxially-oriented polyethylene terephthalate (BoPET). These sheets are used for protecting fruits and other perishable products from moisture.

Top Industries Relying on Mylar Bags

Custom Mylar bags actually have broader applications across various top industries mentioned as follows:

-

Pharmaceutical and Medical Industries

Some people have a misconception that Mylar bag packaging is limited only to the food industry, which is not true. Custom Mylar bags are widely used in the pharmaceutical industry to protect various medicines and essential medical tools against moisture and air.

From powdered medicine sachets to syringe packets, all are made from PET. Smell-proof Mylar bags are used for keeping medicines intact during display, handling, and shipping. Some popular pharmaceutical products packed in mylar bags to ensure extended shelf life include:

Herbal Products

- Capsules & Tablets

- Injections & Syringes

- Powdered & Semi-Liquid Medicines

The Food Industry

Who doesn’t know the application of Mylar bag packaging in the Food industry? Whether you are a businessman or a consumer, visiting a retail store can help you determine how many food items are being packed in custom Mylar bags.

The reason? Obviously, the protective nature of Mylar bags ensures the extended shelf life of food items, especially those that are prone to moisture and humidity. Another frequently asked question is, “Are Mylar bags food-safe?”

The answer lies in the extensive use of Mylar bag packaging in the food industry. Food packaging can not reach the retail shelves if they don’t comply with the FDA’s rules and regulations. And Mylar bags are considered safe by the FDA and can be used for storing food items.

From dry food items to semi-liquid ones, Mylar bags allow you to store them all while ensuring their longevity. Some popular food items packed in custom Mylar bags are as follows:

- Pet Food

- Dry Fruits

- Teas & Coffee

- Rice & Grains

- Flour & Sugar

- Spices & Herbs

- Ketchup & Sauces

- Snacks & Gummies

Electronics and Technology

Another amazing application of Mylar bags is keeping sensitive electronic components and devices from moisture and corrosion. Custom Mylar bags’ tear-resistance protects electronics from external damage during storage and transport.

Also, the excellent barrier properties of Mylar bag packaging protect the technology equipment from electrostatic discharge (ESD). From communication devices to consumer electronics, Mylar bags are ideal for packing all kinds of electronics.

The following are some popular products from the electronics & technology industry that are packaged in Mylar bag packaging:

- Chips & Antennas

- Chargers & Handfrees

- Power Supplies & Batteries

- Circuit Boards & Integrated Circuits

Agriculture and Seed

Mylar bags benefit the agriculture sector with their protective properties to keep their harvested products and essentials that are used for agricultural purposes. These bags can be customized with oxygen absorbers when the products are in bulk quantities and intended to be stored for a longer period of time.

The following popular products from the agriculture industry are often packaged in Mylar bags for superior protection from internal and external damaging factors:

- Plant Seeds

- Seeds & Nuts

- Grains & Cereals

- Dried Herbs & Fruits

- Fertilizers & Herbicides

Cannabis Industry

The use of cannabis is prohibited in various regions and industries. This is why their limitations make it important for industries to store them for an extended period. Custom weed Mylar bags are used to pack all kinds of dried cannabis products. These packs ensure the safe stacking and shipping of cannabis products across pharmacies and other relevant sectors.

Packaging for Consumer Goods

The retail industry highly depends on Mylar bags for ensuring the longevity of FMCGs. Whether it is a food or cosmetic item, the right preservation is done using custom Mylar bags. Food and non-food fast consumer goods are packed and displayed in Mylar bags to ensure user convenience.

Customers can also keep the products safe, unless the products are completely consumed. Some popular FMCGs packed in Mylar bags are as follows:

- Grains and pasta

- Cosmetics and skincare

- Toiletries and sanitation products

- Pharmaceuticals and supplements

- Dehydrated and powdered products

Types of Mylar Bags

Mylar bags come in different types depending on various factors like thickness, style, size, and material. Let’s discuss some major types of Mylar bags based on their material and style:

-

Types of Mylar Bags by Style

Mylar bags are styled using different closing mechanisms, shapes, and designs, making them different from one another. Some popular types of Mylar bags, based on their styles, are as follows:

- Child Resistant Mylar Bags

- Vacuum Sealed Mylar Bags

- Custom-Shaped Mylar Bags

- Smell-Proof Mylar Bags

- Resealable Mylar Bags

- Spout Mylar Pouches

- Die Cut Mylar Bags

- Ziplock Mylar Bags

-

Types of Mylar Bags by Material

The following are some common types of Mylar bags based on their material:

- Clear Mylar Bags

The primary material used for creating Mylar bags is PET, which is a transparent film. So when the bags are purely made from PET, they result in transparent Mylar bags that give a sneak peek at your products.

- Kraft Mylar Bags

Some Mylar bags are easier to recycle than those that are completely made from a thick layer of PET. Kraft Mylar bags are one such type that is made from PET-coated kraft paper. The rustic charm of kraft paper makes brown Mylar bags ideal for packing organic food items like nuts, teas, coffee, spices, and herbs.

- Laminated Mylar Bags

Another type of Mylar bag, by its material, is a laminated Mylar bag packaging, which has multiple layers of materials, including PET. Laminated mylar bags are made by applying an aluminum coating to a strong polyester (mylar) film using vapor deposition, then layering it with polyethylene to provide a moisture-resistant seal.

Features of Mylar Bag Packaging

Generally, Mylar bags are protective due to the material’s barrier properties. These bags are customizable, and their effectiveness can be improved by incorporating some additional features. The following are some excellent features of custom Mylar bags that ensure the added protection from oxidation, gases, moisture, air, and light:

-

Degassing valve

Various perishable products, especially food items, release gases, which make it difficult to ensure products’ longevity even if they are packed in Mylar bags. To maintain the freshness and longevity of such products, a degassing valve is incorporated with Mylar bags, which allows gases like carbon dioxide to release from the bags and prevents oxygen from entering.

One of the best examples of such products is coffee, which releases gases, and they are packed in Mylar coffee pouches that feature a degassing valve to ensure the longevity and freshness of your coffee products.

-

Oxygen absorbers

Another excellent feature of mylar bags is the oxygen absorbers. They are small packets containing iron powder that chemically react with oxygen to remove it from sealed food mylar packaging. Mylar bags with oxygen absorbers are mostly used to store food items for the long term, as they offer an oxygen-free environment for the product.

Benefits of Mylar Bags

Custom Mylar bags offer benefits that uplift various brands in many ways. Some of them are as follows:

- Offer compact storage.

- Ensure the extended shelf life of products.

- Block light and odors from the sensitive products.

- Reduce the products’ recurring manufacturing costs.

- Improve brand awareness when customized perfectly.

- Reduce shipping costs due to their lightweight nature.

Standard Sizes of Mylar Bags

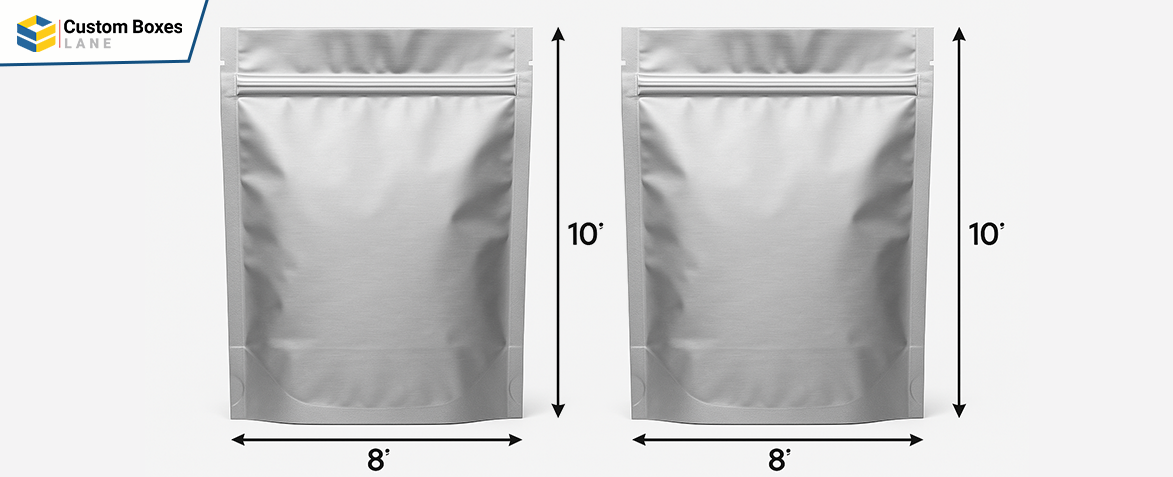

The flexibility of Mylar material allows you to customize bags in every size, shape, and style you want. However, some brands follow the standard Mylar bag size guide to pack their product. Some commonly used sizes of Mylar bags are as follows:

- Small Mylar Bag Sizes: 2”x3”, 3”x4”, and 4”x6”

- Medium Mylar Bag Sizes: 5” x 7”, 6” x 8”, and 7” x 9”

- Large Mylar Bag Sizes: 8” x 10”, 9” x 12”, and 10” x 14”

- Extra-Large Mylar Bag Sizes: 12” x 16”, 14”x 18”, and 16” x 20”

Thickness for Mylar Bags

When measuring size, one should never ignore the thickness of Mylar bags, as it directly impacts the effectiveness and weight of the bags. The standard thickness of thin mylar bags used for packing small products for the short term is 2-3.5mil. It goes to more than 10 mil depending on the products’ storage needs. The higher the thickness, the longer the product’s shelf life.

Environmental Impact of Mylar Bags

Most people might have a question: Are Mylar bags toxic to the environment? The answer to this question lies in the material complexities and recycling programs. Generally, Mylar bags are not easy to recycle nor accepted by curbside recycling programs because they may contain aluminium foil and PET.

However, the tear-resistant properties of Mylar bags make them ideal for reuse if properly cleaned. Brands can promote the circular economy for a safe environment by enhancing the reusability of Myar bags. Another factor that may reduce the environmental impact of Mylar packaging is using Brown Mylar bags made from kraft paper. If the ratio of kraft paper is higher and PET is lower, kraft Mylar bags could be a better option.

Mylar bags support printing and customization, which allow brands to portray their brand stories compellingly.

Things to Consider When Customizing Mylar Bags

You must understand the nature and needs of your products when customizing Mylar bags. Also, determine your brand personal to customize the Mylar bag design that aligns with your brand personality and product needs. Customize the thickness of Mylar bags according to the quantity and needs of your products.

Never forget to ensure your Mylar bags comply with the FDA’s regulations. Get them customized with responsibly sourced materials and inks for food safety. Proper labeling and branding elements must be printed on the PDP to ensure your Mylar bags stand out on the retail shelves.

Factors Influencing Mylar Bag Costs

Are Mylar bags cost-effective? The answer to this question depends on the following factors:

- Size: The size of Mylar bags directly affects the cost of the bags.

- Thickness: Mylar bags with higher thickness are more protective yet costly.

- Quantity: Buying Mylar bags wholesale proved to be more cost-effective.

- Material: Depending on how many layers of materials you want to incorporate.

- Customization: Printing, shape, style, design, and additional features impact the cost.

Considering the benefits of Mylar bags, they are cost-effective and offer you value for money.

Future of Flexible Mylar Packaging

The current growth of the Mylar bag market depicts its bright future because of the extensive use of custom Mylar bag packaging across various industries. A market forecast report shows polyethylene terephthalate (PET) CAGR of 4.1% during the forecast period of 2023 -2030.

Some 2025 trends for custom Mylar bags focus on sustainability, high-end aesthetics, and technological integration. However, sustainbilty is still a challenge when it comes to Mylar bags.

Now, sustainable innovations are used for Mylar bags that can be made from recycled and bio-based materials, derived from sources such as corn starch and cellulose.

Another trend for reducing environmental impact is the use of minimalistic Mylar bags. These bags are customized with energy-efficient printing and eco-friendly inks.

Mylar bags are also seeing increased application in pharmaceuticals and other sectors for extending shelf life.

Conclusion!

The significance of Mylar bags is undeniable due to their excellent benefits. These bags are made from materials that ensure moisture-resistance to ensure the extended shelf life of products across various industries, including food, pharmaceuticals, retail, FMCG, agriculture, and chemicals.

However, Mylar packaging also has some challenges, such as higher costs and environmental impact, but still, the money invested in these bags offers value for money. These bags are designed in various styles using customization. The irresistible benefits of Mylar bags depict a bright future for its market!

Mylar bags are ideal for storing food items and other perishable products to ensure an extended shelf life because of their multi-layer structure, barrier properties, and airtight sealing. PET has excellent barrier properties that ensure food safety against moisture, air, light, and oxidation. However, some Mylar bags contain oxygen absorbers to make the packaging more effective for long-term food storage. A degassing valve can also be attached to the Mylar bags to store food items that release gases.

The standard mylar bag thickness depends on the item that is being stored in the bags for a certain shelf life period. Thickness ranges between 2-10mil and more. Generally, standard thin Mylar bags have a thickness of around 2 to 3.5 mil.

The thickness of the Mylar bag is chosen on the basis of the product's sensitivity to moisture, air, and light. Some small standard Mylar packs have 2-3 mil thickness, which is best for short-term storage. Heavy-duty Mylar bags with 6-7 mil thickness are used for storing items like beans, rice, grains, and granolas.

No! Mylar bags are not toxic because they have been extensively used in the food industry for years to store food for long periods of time. Their materials are safe. However, they are not easy to recycle, but some specialized recycling facilities accept them for recycling to ensure they don’t harm the environment.

The environmental impact of custom Mylar bags depends on the material, customization, and ratio of PET used in them. Typically, mylar bags are not easy to recycle, and many recycling programs don’t accept them because they may contain multiple layers of aluminium foil and PET.

The effectiveness of vacuum bags and Mylar bags depends on their usage. If you want to store products for the short term, vacuum bags are better than Mylar bags. Vacuum bags are designed to remove air from within to ensure moisture resistance and create a vacuum-sealed environment. On the other hand, Mylar bags are better for storing perishable products for a longer period of time.