Rigid vs. Folding Cartons: Which Is Best for Premium Products?

Waqas Khan Pitafi 2026-01-19 12:54:37

Packaging serves as a “silent ambassador” for product-based businesses in the modern era. Its main purpose is no longer limited to basic protection. Modern packaging has become an essential tool of your brand’s identity.

If you’re experimenting with various packaging types, the choice becomes significant. Each packaging type has unique properties. The type you choose influences both design aesthetics and functionality.

The most common packaging types are folding cartons and rigid boxes. Both have some similarities, but they are quite different. This blog sheds light on rigid vs. folding cartons to help your business choose the right option between them.

What are Folding Cartons?

As their name suggests, cartons have a flat construction that folds into shape when needed. That’s why they are called “folding cartons.” These cartons are mainly made from paperboard. Their capacity for easy storage and endless customization gives them a competitive edge in the packaging market.

Usually, the retail, cosmetic, and food industries use folding cartons due to their cost-effectiveness and appealing look.

Pros of Folding Cartons

Folding cartons are cost-effective, lightweight, and highly customizable for branding. Yet they have some cons, like limited structural protection for heavy items. Let’s dive deep into their pros and cons:

-

Structural Integrity

Though folding cartons are versatile, it doesn’t mean they compromise their durability. In fact, they offer superior protection for multiple items of varying shapes and sizes. But they act as a protective shield for lightweight items more effectively than for bulky or heavier items.

-

Printing Capacity

When it comes to printing, folding cartons never disappoint you. These cartons show off impressive and high-quality graphics that enhance your product appeal and brand credibility. Since they are made from paperboard, their smooth surface serves as an excellent canvas for vibrant, crisp, and detailed imagery.

You can also represent your brand well by designing your folding cartons with embellished finishes. The paperboard often has multiple layers of coating on the printing surface, which ensures a high-quality base for vibrant colors and intricate designs.

The inherent structure of paperboard provides a stable base that can withstand the pressure and heat involved in processes like embossing or hot foil stamping.

-

Cost-Effectiveness

Many businesses prefer folding cartons over other packaging solutions due to their budget-friendly production process. Paperboard is cheaper than plastic, glass, or metal and is suitable for high-speed cutting and printing on single sheets.

It eventually minimizes waste and labor while reducing unit costs. The lightweight nature and ability of cartons to ship flat before assembly drastically cut transport and warehousing expenses.

-

Impact on Environment

Since they are primarily paper-based, folding cartons are naturally biodegradable, breaking down into organic matter without releasing harmful microplastics or toxins into the environment. Also, paperboard has a very high recycling rate (approximately two-thirds of U.S. domestic waste is recycled).

As a result, folding cartons are widely accepted in curbside recycling programs. The recycling process for paperboard often has a lower carbon footprint than producing virgin materials or recycling certain plastics.

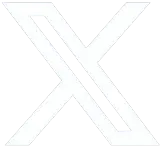

Pros and Cons of Folding Cartons

Since you have explored the pros and cons of folding cartons in detail, now weigh them too. Let’s have a look at the following table:

|

Pros |

Cons |

|

Economical for mass production, with lower unit costs and cheaper shipping (flat). |

Less sturdy than rigid boxes, offering less shock absorption and security for delicate items. |

|

Reduces shipping weight and costs, and saves storage space. |

Can deform or get crushed, especially with heavy products; often requires internal inserts for support. |

|

Excellent for high-quality graphics, branding, stamping, embossing, and eye-catching retail displays. |

Paperboard isn't waterproof and can be damaged by water without a poly-liner. |

|

Collapsible design allows them to be shipped and stored flat, optimizing logistics. |

Needs assembly (folding/gluing) at the user's end, unlike pre-assembled rigid boxes. |

|

Often made from recyclable and biodegradable paperboard. |

Typically single-use, unlike some heavier-duty options, and not reusable |

|

Can be designed in many shapes and styles for various products like cosmetics, pharmaceuticals, and food. |

Heavy, fragile, or luxury items needing maximum protection or premium, non-collapsible packaging. |

What are Rigid Boxes?

Like folding cartons, rigid boxes are also made from paperboard. But chipboard layering is also used to make these boxes. They have a solid structure and a premium feel, which makes them popular for luxurious and gift brands.

Apart from premium and luxurious items, you can also pack sensitive items like electronics, cosmetic formulations, perfumes, and candles in luxury rigid boxes.

Pros and Cons of Rigid Boxes

Rigid boxes have diverse benefits such as superior durability, protection, and a premium look. But they also have disadvantages like higher cost and increased storage space. Firstly, consider their pros:

-

Structural Integrity

The word “rigid” in these boxes stands for solid structure. The core of a rigid box is typically a dense, high-thickness paperboard (often 1.5mm to 3mm thick), such as greyboard or chipboard. This substantial construction provides inherent durability and prevents the hard box packaging from easily bending, crushing, or deforming under pressure.

-

Printing Capacity

Rigid boxes are compatible with numerous advanced printing and finishing techniques that are difficult or impossible to apply effectively to standard folding cartons. These techniques include offset and digital printing, speciality finishes (e.g., foil stamping, embossing, Spot UV), coatings, and laminations.

With these options, a well-designed and high-quality rigid box conveys a sense of luxury and attention to detail, making your brand products feel more valuable to the consumer.

-

Cost-Effectiveness

Compared to folding cartons, rigid boxes are expensive due to their complex and labor-intensive manufacturing process. They involve wrapping thick chipboard with decorative paper, which requires skilled labor and specialized equipment.

Also, higher material needs for sturdy boards and luxury finishes like metallic foiling, embossing, and satin lining raise their manufacturing costs. However, the initial cost of rigid setup boxes might be more than folding cartons.

But the benefits, like brand identity, reduced product damage, and marketing power, often help businesses like yours get a better ROI.

-

Impact on Environment

When it comes to sustainable packaging, rigid boxes struggle to support green credentials. Their layered and often laminated construction makes the recycling process difficult. The usage of materials like chipboard makes the recycling process of rigid boxes complicated. Moreover, their bulk and weight lower truckload efficiency, which raises shipping costs and carbon emissions.

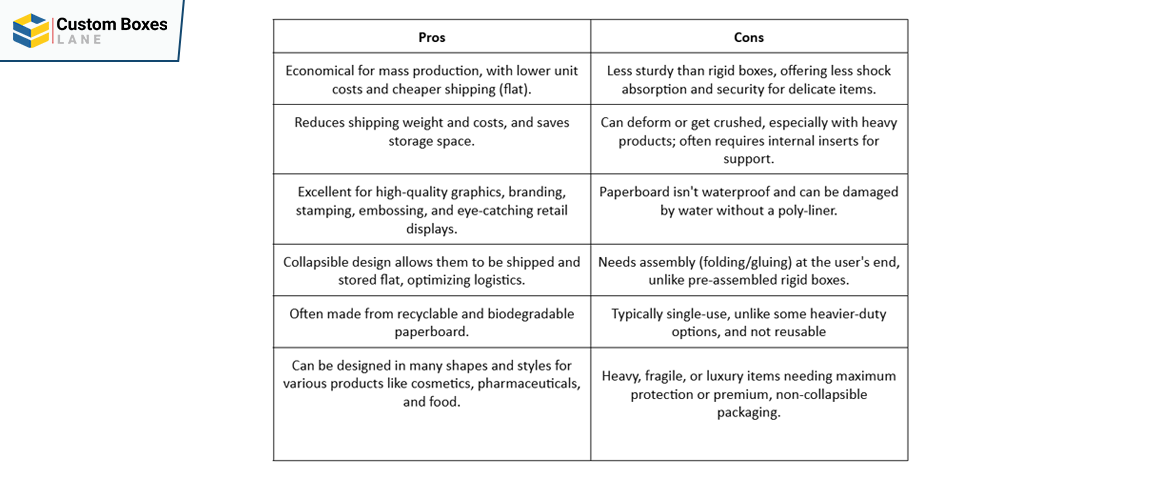

Pros and Cons of Rigid Boxes

Simply put, rigid boxes are great for high-value goods but less economical for everyday items due to their bulk and expense. Weigh their pros and cons in tabular form:

|

Pros |

Cons |

|

Convey luxury and high value while attracting exclusive customers. |

More expensive to produce than folding cartons or flexible packaging |

|

Strong and durable enough to protect delicate contents from damage during shipping and handling. |

Non-collapsible nature means they take up significant space in storage and during shipping. |

|

Provide a memorable, high-quality experience to elevate your brand perception. |

Bulkiness can increase shipping costs and warehouse needs. |

|

Retain their shape even when empty, unlike flexible packaging (like folding cartons) |

Can have a higher environmental footprint and be harder to recycle |

|

Offer high-end printing, finishes, and unique opening mechanisms (like magnetic closures). |

Less adaptable for irregularly shaped items or bulk packaging compared to other types. |

Similarities Between Rigid and Folding Cartons

Until now, you have navigated through both types in detail individually. Let’s consider the similarities in their properties before comparing rigid vs. folding cartons:

- Material Base:Both are made from paperboard, though the thickness varies significantly.

- Customization: Both types allow for extensive design, with options for unique shapes, styles, and high-quality finishes.

- Printing and Finishes: They can both utilize advanced techniques like foil stamping, spot UV, embossing, debossing, and soft-touch coatings for premium branding.

- Branding & Marketing: Both serve as effective marketing tools to communicate product information and brand identity.

- Versatility: Both are suitable for a wide range of products, from cosmetics to electronics.

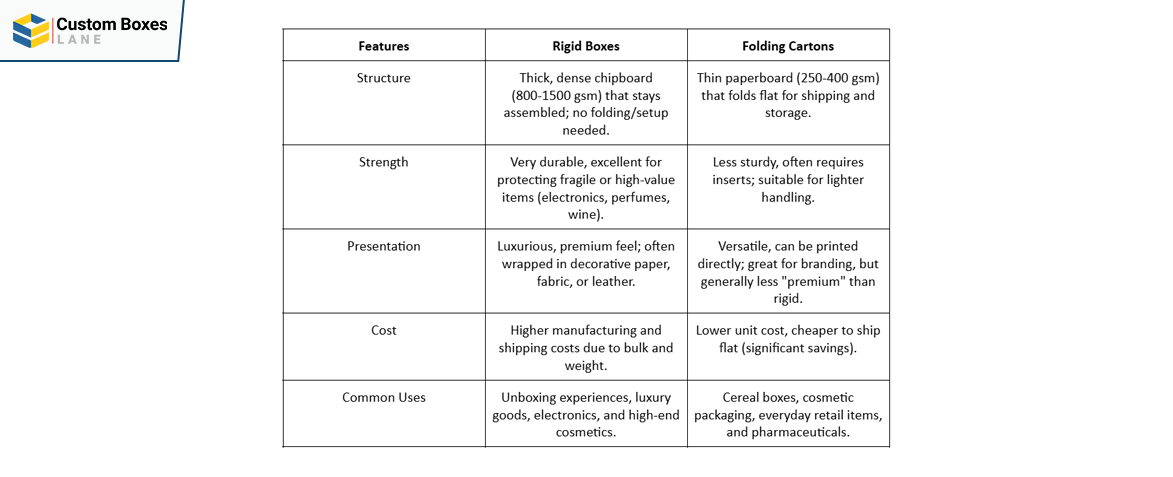

Comparative Overview of Rigid vs. Folding Cartons

Apart from their similarities, let’s consider rigid vs. folding cartons. There are plenty of differences between them, but have a look at the major ones:

|

Features |

Rigid Boxes |

Folding Cartons |

|

Structure |

Thick, dense chipboard (800-1500 gsm) that stays assembled; no folding/setup needed. |

Thin paperboard (250-400 gsm) that folds flat for shipping and storage. |

|

Strength |

Very durable, excellent for protecting fragile or high-value items (electronics, perfumes, wine). |

Less sturdy, often requires inserts; suitable for lighter handling. |

|

Presentation |

Luxurious, premium feel; often wrapped in decorative paper, fabric, or leather. |

Versatile, can be printed directly; great for branding, but generally less "premium" than rigid. |

|

Cost |

Higher manufacturing and shipping costs due to bulk and weight. |

Lower unit cost, cheaper to ship flat (significant savings). |

|

Common Uses |

Unboxing experiences, luxury goods, electronics, and high-end cosmetics. |

Cereal boxes, cosmetic packaging, everyday retail items, and pharmaceuticals. |

Which One Should You Choose for Premium Products?

As you have compared properties and features of rigid vs. folding cartons, you can understand that each type serves unique purposes. If you sell premium items, then rigid boxes are a superior choice due to their superb durability and memorable unboxing experiences that justify a higher price point.

But if you want a reliable, stylish, sturdy, and cost-effective packaging solution for high-volume retail items, folding cartons are a good-to-go choice. Whether you want to customize rigid boxes or folding cartons, contact Custom Boxes Lane to enjoy premium quality at wholesale rates.

A folding carton is a lightweight, versatile paperboard box. It is made from a single sheet that's printed, cut, creased, and folded to create a container for consumer goods.

Rigid boxes offer superior protection, durability, and a premium aesthetic while creating a luxurious unboxing experience that elevates brand perception and customer satisfaction.

An example of rigid packaging is a glass jar for pasta sauce, a metal can for soup, a cardboard cereal box, or a plastic bottle for soda. These are all firm containers that maintain their shape and offer structure and protection for the product inside.

The main difference is structure. Rigid boxes are sturdy, non-collapsible, premium boxes made from thick chipboard, while folding cartons are made from thinner and foldable paperboard.