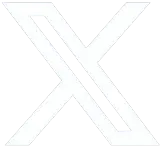

Types & Benefits of Die-Cutting Process in Packaging

Waqas Khan Pitafi 2026-02-18 11:43:00

The process of die-cutting begins with the creation of dielines, created by the designers, which act as a 2D blueprint or template for the final 3D packaging. After this, the lines were processed into the die-cutting machine to create precise, repeatable shapes for packaging, labels, and other materials.

This process is now frequently used by brands to compel custom packaging more quickly and easily, allowing for custom shapes and cost-effectiveness for large production runs.

In case your packaging demands sharp precision, intact shapes, and creasing in one fast pass, then the die-cutting process can be your ally in 30% cost reductions, minimizing waste and large runs. Read on!

What is a Die?

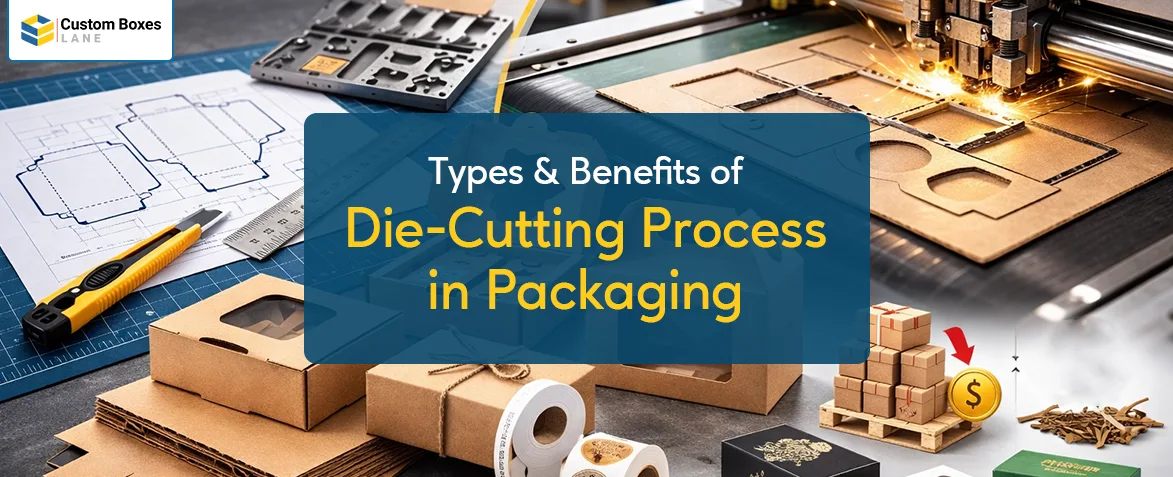

Think of a die as a cookie-cutter (giant one) that is used to cut and mould any shape of packaging materials with the aid of a press. These metallic tools (usually steel-rule dies) are crucial for creating precise folding cartons and custom boxes, ensuring uniformity across high-volume production.

Can you Use Dies More Than Once?

Using one die for different packaging of the same shape but with different designs and styles is the best and recommended option for brands seeking an affordable and cost-saving procedure. With one die, you can create 100 boxes. They are highly durable, allowing for repeated, long-term use in crafting.

Tip: To extend the die lifespan, you can flip cutting plates to avoid warping or use them for embossing.

Understanding the Process of Die-Cutting

To understand the process of die-cutting, keep in mind that to construct any shape, there is a process involved called “die-line”. This process made the die-cutting procedure easier with the help of modern technologies.

For instance, CAD software is used to create dielines. This process ensures you get cut lines, bleed lines, fold lines, and safe zones properly mapped out in the die line before moving forward with the die-cutting process.

Then, cutting die uses strips of metal called rules or steel rules. The cutting ruler is formed into shape using a rule bender, which bends, cuts, and notches steel into the shape needed.

Some of the most common rule options are:

- Through cutting: Cuts through the packaging material

- Scoring: Rather than cutting the whole way through the material, scoring leaves an impression, an indent, or a partial cut on a single stress point.

- Creasing: Used to create a fold line for convenient construction

- Perforating: A series of small cuts that create a weak point for tearing.

Types of Die-Cut Techniques

Now you have understood how the die-cutting process is used to create custom, accurate, and repeated shapes. Here are the types of die-cutting techniques with different uses and benefits that you can choose for your die-cut packaging boxes:

-

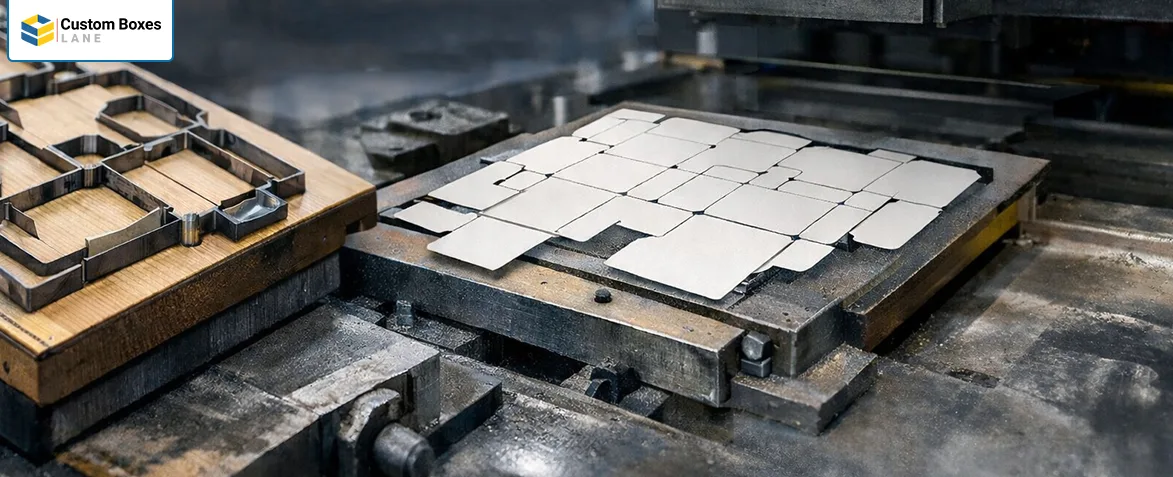

Rotary Die-Cutting

Rotary die cutting is the most effective method for high-speed and precise die-cut cardboard packaging and other materials manufacturing processes. This technique is in the form of cylindrical, rotating dies with sharp blades that is press to cut, crease, or perforate materials.

Rotary die-cutting often involves non-metallic or flexible substrates which fed from a roll. It is highly efficient for creating complex, high-volume, and precise shapes for packaging, tags, and components, all in a single pass.

-

Flatbed Die-Cutting

The flatbed die-cutting process is one step ahead of rotary. It is an ideal option to cut shapes for low-volume projects. One significant move is flatbed can cut easily into thick sheets without hassle.

It’s like a hydraulic process that uses custom steel rule dies to cut, crease, or shape materials like paper, board, plastic, and foam. It is ideal, yet ot limited to short-to-medium runs, thick materials, and complex shapes. One of the most effective tools for packaging and industrial applications.

-

Digital Die-Cutting

Digital die cutting is a computer-controlled, blade-based technology used to precisely cut, score, and shape materials such as paper, vinyl, and cardstock without physical dies.

It is ideal for short-run, custom, or complex designs in packaging and labels, offering fast, on-demand, and cost-effective production without a die template, costs.

Die-Cutting Methods

Apart from different functions, the techniques of the die-cutting process, it also practice different methods for more precision, accuracy, and cost discrepancies.

There are numerous types of die-cutting methods, including;

Blanking:

This method, which cuts a shape from a flat sheet, is often used for removing excess material around a cut piece for a precise shape and is called blanking.

Drawing:

This method is also referred to as “deep drawing,” in which material is pulled into a die cavity, using a punch to transform a flat bank into a hollow and three-dimensional cup shape. It is used for creating long, thin, or cylindrical shapes.

Forming:

This method shapes material by bending or stretching it on a curved surface without removing any material. It is often used in tandem with drawing to create rounded, complex, or cylindrical parts in packaging.

Coining:

A precision, high-pressure, cold-forming process that squeezes a metal blank between two dies. Coining forces the metal to flow and take on precise, intricate, and detailed shapes or impressions, such as in the creation of coins or raised, fancy features on packaging.

Role of Dielines in Die-Cut Process

As mentioned earlier, the dieline in the die-cutting process is essential as it decides the accurate blueprint in the die-cut process. This decline determines the mapping out process, as to where the packaging will be cut, folded, creased, and perforated.

It also provides ease to designers and manufacturers, and gives direction for a perfect cut box. Because if we cut without dielines it can create multiple errors, and material waste. That’s why their importance in die-cutting can not be overlooked.

Conclusion

It is proven that without the die-cutting process, the creation of artisan, accurate, and unique boxes at Custom Boxes Lane would be hindered, making it impossible to deliver highly precise and perfectly structured packaging. Whether you are making bulk packaging or single packaging die-cutting process is important for highly appealing branding.

Die-cut packaging boxes are a manufacturing process that uses specialized, sharp steel-rule dies to cut, score, crease, or perforate materials, like cardboard, paperboard, or plastic, into custom shapes and designs.

A die-cutting packaging machine is a tool that cuts intricate designs from materials like paper, card, fabric, and thin metal by applying pressure through its sharp metal shape, called a die. The machine can be manual, you can operate it by a hand crank, or electronic, which is powered by a motor.

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies (used in the manufacture of wire) and casting dies (used in molding), which are not.