A Comprehensive Guide on What is Cardboard and Its Types

Waqas Khan Pitafi 2026-02-25 14:39:00

Cardboard is a staple packaging material that plays a significant role in our daily routines. It serves multiple purposes, from packaging and shipping to crafting and structural support. Cardboard packaging is popular for its lightweight yet robust nature.

Its eco-friendly nature also makes it an outstanding alternative packaging solution to plastic and non-ecofriendly materials. Let’s dive deep into learn what is cardboard in detail!

What is Cardboard?

Put simply, cardboard is a strong paper-based material. It is commonly used for packaging and retail displays. This packaging material is made of layering pulp or recycled fibers, which makes it durable. Despite being sturdy, it's also lightweight in nature, streamlining the shipping process. In crux, its durability, affordability, and recyclability make it a popular choice for manufacturing food boxes to shipping cartons.

The Importance of Cardboard

Some characteristics give cardboard packaging an edge among other packaging solutions. Have a look at these characteristics:

- Shields Products from Damage: Keep your products intact while ensuring they arrive pristine at the final destination. Cardboard boxes are durable enough to absorb shocks and vibrations during shipping.

- Enhances Logistics Efficiency: Improve overall logistics efficiency with the stackable structure of cardboard. Its structure and lightweight reduce shipping costs because they optimize space in transport vehicles and warehouses.

- Supports Environmental Sustainability: Conserve natural resources like trees, as cardboard is derived from wood pulp, which is a renewable resource. Also, cardboard is 100% recyclable, which can be reprocessed multiple times while reducing landfill waste.

- Boosts Brand Visibility: Offer an excellent surface for attractive graphic design, making cardboard packaging an integral part of product marketing and brand visibility. Cardboard boxes are flexible to endless customization to be designed in any size, style, or finish.

- Becomes Budget-Friendly Packaging: Serve as a cost-effective packaging solution for consumers and businesses due to its low production and raw material costs. Since it is lightweight, it reduces the overall shipping costs.

What is Cardboard Made of?

Cardboard is a material that is used to manufacture boxes and packaging for many items we buy, like cereals, toys, and bottles. It is derived from paper pulp that is created by disintegrating fibres present in trees and plants.

This packaging material is also known as “Corrugated Cardboard” because of its corrugated structure. The structure refers to the process where flutes are added between two layers of paperboard. This process is called “Corrugation.” Due to the flexible customizability of cardboard, you can design it in different thicknesses, colors, and textures to meet various packaging needs.

Explore Types of Cardboard Paper

Consider different types of cardboard paper based on its middle corrugation or layering. Each type serves a unique purpose:

-

Single-Faced Corrugated Board

It is also known as “Corrugated Rolls.” Single-faced corrugated board is made of two layers: a flat linerboard and a single layer of fluted paper glued to it. Its layering structure results in one flat side and one with raised “waves.” This type is ideal for wrapping odd-shaped items like pillows while preventing them from damage during shipping.

-

Single-Wall Corrugated Board

It is a three-layer material that is comprised of two flat outer liners and a single, wavy layer of fluting (corrugated medium) in between. This structure provides lightweight strength, compression resistance, and a cushioning effect for light to medium-weight items in shipping boxes, storage, and handling. The versatility and affordability of single-wall corrugated board make it a popular packaging choice.

-

Double-Wall Corrugated Board

Double-wall corrugated board is a heavy-duty packaging material. It is made of three flat linerboard sheets and two layers of corrugated fluting in between. This structure creates a much stronger and more rigid structure than a single-wall board. The double-layer construction of cardboard boxes offers superior protection for heavy items like furniture and appliances.

-

Triple-Wall Corrugated Board

This corrugated board is a heavy-duty and 7-layered packaging material. It is made of four layers of inner board and three layers of fluted and wavy medium. This layering structure offers significantly higher compression strength compared to standard double-wall boxes. It is an effective and economical choice for packaging industrial items like motors and compressors.

The Manufacturing Process of Cardboard

Here is a step-by-step guide to learn about the manufacturing process of cardboard packaging. Let’s jump right into it:

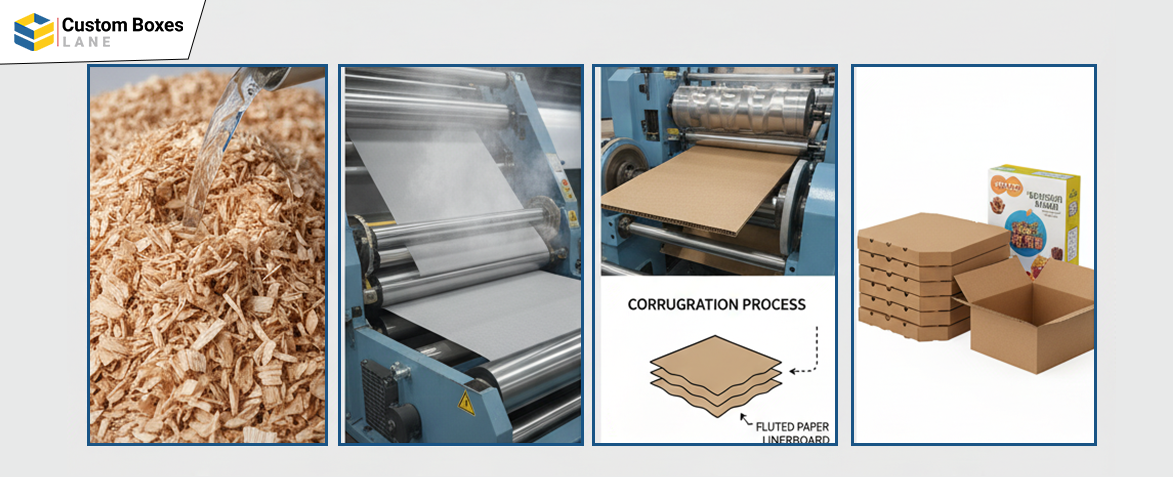

- Pulping: The manufacturing of cardboard begins with the creation of wood pulp from trees. Firstly, wood is chopped. And then it is mixed with water and chemicals to remove impurities while breaking down fibers.

- Cleaning: After extracting pulp from trees, the pulp slurry is pumped through various screens and filters to remove larger contaminants. Plastic coatings, tape, labels, and metal staples are among those contaminants.

- Bleaching: If a white or lighter color is needed for the final product, the pulp may undergo a bleaching process. A thorough washing process removes any remaining chemicals, ink, and sticky residues from the pulp.

- Forming: After bleaching, pulp is transformed into flat sheets by using a machine called the “Fourdrinier.” Then, pulp is poured onto the flat surface of the sheets and drained. It eventually forms a layer of pulp.

- Pressing: The sheets are spread onto a conveyor and passed through a series of heated cylinders to remove excess water. Then, large and heavy-duty rollers squeeze out moisture and compress the fibrous material, which turns into a compact and durable sheet of paper.

- Corrugation: In the next process, a single sheet of paper is fed into a corrugated machine. This machine is used to create a wavy shape, known as flutes. The single-faced corrugated board continues through the machine to create a double-faced corrugated board.

- Cutting and Shaping: Finally, a sheet of corrugated material is fed into a die-cutting and creasing machine. The sharp metal rules on the machine precisely cut out the profile of the box and any required windows or cutouts.

Is Cardboard Paper Eco-Friendly?

In the modern era, sustainable packaging is as important as it’s ever been worldwide. Most consumers are seeking eco-friendly options to reduce the environmental impact of packaging. Cardboard fulfils this criterion fantastically.

Cardboard is renewable, recyclable, biodegradable, and compostable. Since it is made from wood pulp, a renewable raw material that can be sustainably managed through practices like those certified by FSC. Cardboard also has a high recycling rate in many regions. It can be recycled multiple times, which reduces the need for virgin wood, water, and energy.

Made from cellulose, cardboard can naturally break down into organic matter, which reduces landfill dumps. Similarly, if cardboard is unbleached, it decomposes into soil and becomes beneficial for compost heaps.

Why Businesses Should Use Cardboard?

Several global industries are seeking eco-friendly packaging to promote a green environment. Here are certain reasons to choose cardboard for your packaging business:

- Recyclability: Cardboard material is reusable. It can be transformed into new products because it is highly recyclable. As a result, this material reduces waste and promotes sustainability.

- Durability: The layering structure of cardboard with the addition of flutes makes it durable and crush-resistant, while becoming ideal for shipping fragile items.

- Versatility: You can customize cardboard in versatile shapes and sizes by cutting and folding due to its flexible nature. Cardboard is also suitable for high-quality prints.

- Affordability: Businesses seeking a reliable yet cost-effective packaging solution, cardboard serves best due to its lightweight nature.

Conclusion

Whether you are seeking a durable, sustainable, versatile, and cost-effective packaging solution, there is no better solution than cardboard. From considering its definition, types, manufacturing process, to uses, we have discussed everything in detail in this blog.

In case you want high-quality cardboard packaging boxes with premium customizability, contact Custom Boxes Lane to boost your brand visibility and ensure product protection.

Cardboard paper is a multi-layer material that is primarily used to create boxes for shipping and storage. The layers of kraft paper are glued together to create a robust fiberboard called cardboard paper.

Cardboard is also known as corrugated fiberboard. This is primarily used to create durable packaging that can pack and keep safe a lot of items. The strength of this material is backed by multiple layers of kraft glued together.

Three major types of cardboard are single-wall cardboard, double-wall cardboard, and triple-wall cardboard. These types determine the thickness and number of layers that cardboard has.

The main use of cardboard is creating robust packaging cartons. These cartons are used to store endless products, from lightweight to heavy-duty. Also, cardboard helps create excellent branded retail packaging and mailer boxes for e-commerce product delivery.