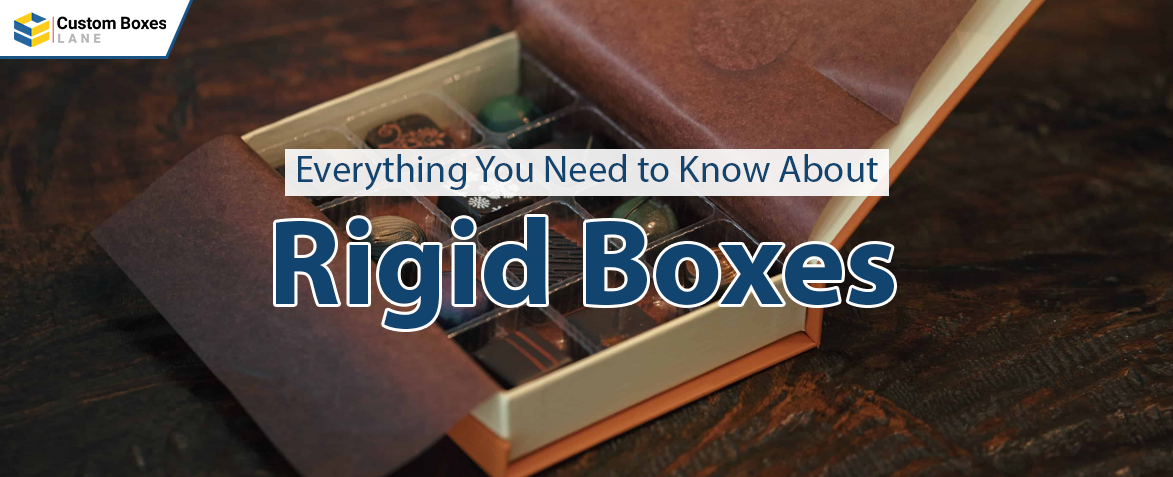

Everything You Need to Know About Rigid Boxes!

Waqas Khan Pitafi 2025-09-24 12:56:28

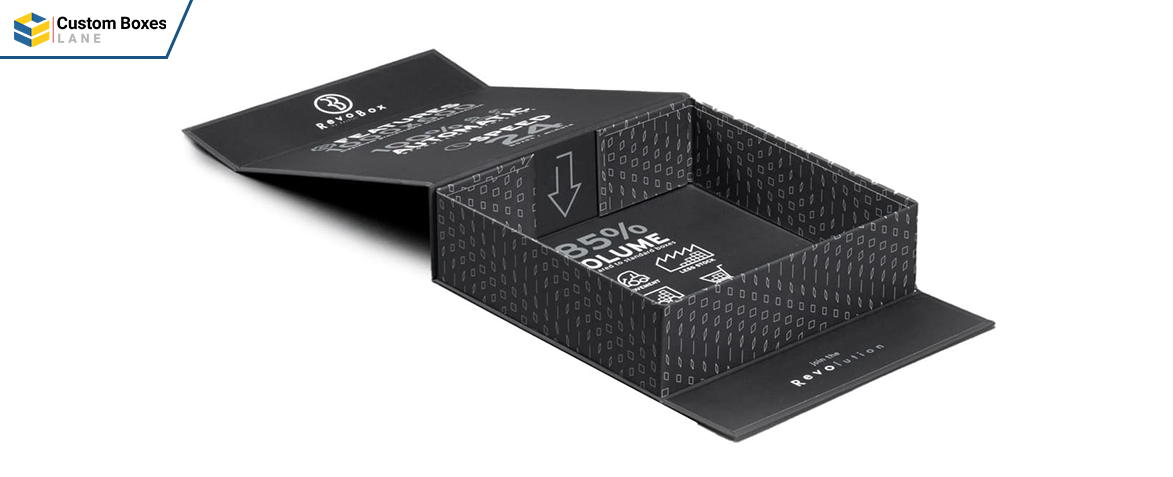

When you pick up a luxury product like a new phone, a designer watch, or even a fancy box of chocolates, have you noticed how stylish and solid the box feels? That’s no accident. Those are actually rigid boxes.

These boxes are designed to make the product feel special before you even use it. Unlike flimsy cartons, rigid boxes are sturdy, elegant, and built to impress. If you are new to packaging and curious about what makes them so popular, you are in the right place.

In this blog, you get to know everything about rigid boxes that you should!

A Brief Overview of Rigid Boxes?

Rigid boxes are a premium and sturdy kind of boxes that stand upright even when they are empty. Unlike folding cartons or corrugated boxes, which can collapse or flatten, rigid boxes are designed with thick and inflexible boards.

Made from chipboard or paperboard, rigid boxes often wrap in a decorative paper for a more luxurious feel. These boxes have high structural integrity that resists bending and crushing. They are usually used for high-end products like jewelry, gifts, electronics, and perfumes.

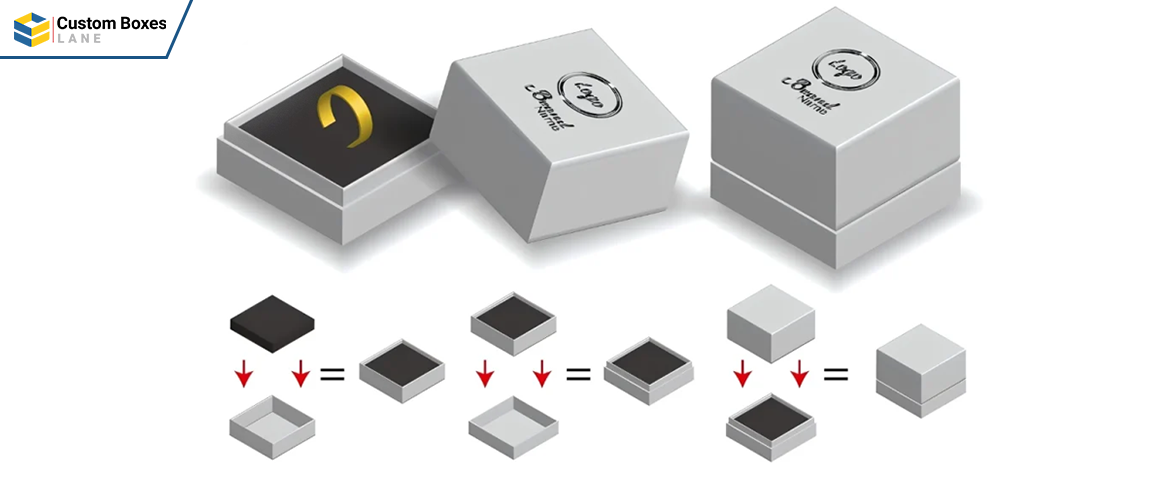

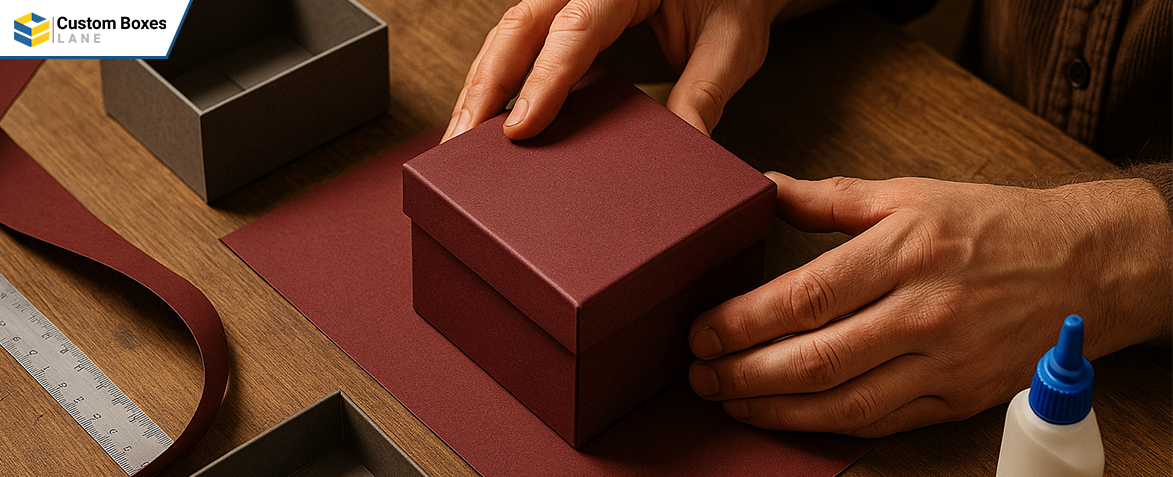

How are Rigid Boxes Made?

In the first step, chipboard or paperboard is cut, scored, and taped to form the base and lid structure of the box. Then, a printed paper wrapped with premium finishes is precisely glued and adhered to the outside of this sturdy board structure. That’s how rigid boxes get their sturdy structure, along with a high-end appearance that most customers love.

Pros and Cons of Rigid Boxes

Like other packaging options, rigid boxes also have their strengths and weaknesses. Let’s look at what makes rigid boxes great, and what drawbacks one should know to find out whether they are a good fit for them or not!

Pros

Rigid boxes provide a memorable unboxing experience and excellent customization, making them an ideal packaging solution. Here are the pros of rigid boxes:

-

Premium Appearance and Unboxing Experience

Since boxes are rigid, they feel solid and tough in the hand. And when they are decorated with premium finishes, magnetic closures, and inserts, rigid boxes elevate the perceived value of both brand and products.

-

Protection and Durability

Rigid boxes are awesome for protecting fragile or high-value items. They resist crushing better than soft or folding boxes. Moreover, rigid setup boxes enhance shelf stability, appeal, and stacking, which is significant for effective display and stacking.

-

Brand Differentiation

In saturated markets of luxury goods like jewelry, cosmetics, and tech gadgets, packaging is a key point of difference. However, a rigid box can help your products stand out and build a unique identity for your brand.

-

Unmatched Customization

When it comes to customizing rigid boxes, they have lots of choices in terms of shape, size, material, finishes, and internal layout. With the power of unmatched customization for logo and colors, luxury rigid boxes convey brand messaging effectively.

-

Reusable Storage Boxes

Many customers don’t throw rigid boxes out; they keep them for storage or as gift boxes. This practice increases the “afterlife” of rigid packaging. As a result, a long-term impression of the brand has been created on buyers.

Cons

As rigid boxes have advantages, they also come with some disadvantages. Carefully read them to make the right decision:

-

High Cost

In production, rigid boxes use more material, go through manual finishing, and undergo extensive quality checks. While the less compressible make and heavier weight of rigid boxes during shipping raise costs.

-

Lead Time

Creating rigid boxes tends to take longer for design, finishing, and assembly. Especially if custom inserts, magnet embedding, etc., are involved.

-

Logistic Challenges

Because rigid boxes are non-foldable, they cover more space in transport and storage. That’s why flat-pack options like collapsible rigid boxes minimize this but often add complexity.

-

Heavier Weight

Heavier materials are used in rigid boxes that raise shipping costs for both retailers and customers. Rigid boxes are a relatively expensive packaging solution compared to other boxes.

-

Environmental Impact

If not designed carefully, like the choice of materials, recyclability, coatings, and adhesives, rigid boxes won’t meet your sustainability requirements. Additional wrappings, laminations, and foil coatings can reduce recyclability.

Why Choose Rigid Over Other Box Types?

To understand what makes rigid boxes special, it helps to compare them with other popular types of packaging. Talking about folding cartons, they are flexible and collapsible. However, corrugated boxes are rigid and heavy, making them ideal for shipping. Contrarily, rigid boxes are non-collapsible, very stiff, and highly premium with a luxurious look.

A Comparative Overview of Folding Carton vs. Corrugated Box vs. Rigid Box

Let’s have a detailed comparison of all three popular packaging styles to help you choose the right type of packaging for your needs:

|

Box Types |

Pros |

Cons |

Folding Cartons |

Lightweight and versatile High-quality printing capabilities Shorter lead times Economical for large production runs Recyclable and sustainable |

Limited structural integrity for heavy or bulky items Aesthetic constraints on special finishes like embossing |

Corrugated Boxes |

Durable and strong Flexible printing options Cost-effective Economical for shipping and storage Recyclable and reusable |

Limited aesthetics for retail presentation Challenges in printing details due to bleeding inks Considerations for customization costs |

Rigid Boxes |

Sturdy and luxurious presentation High-end finishing options Premium packaging appeal Considerations for brand perception |

Limited flexibility for certain products Higher costs for elaborate printing Longer lead times Challenges in recycling and repurposing |

Materials and Construction

The manufacturing of a rigid box involves several key components. Knowing them helps you understand cost, customization, durability, and aesthetic options.

-

Core Material

The skeleton of the rigid box is prepared with thick panels of chipboard or greyboard. They are usually 2 - 3 mm thick or sometimes more. However, paper or board stock is used to give boxes rigidity and serves as a surface to wrap or print.

-

Wrapping and Finishing

After choosing core material, it is wrapped with decorative paper, cloth, specialty paper, or textured surfaces. The wrapping can cover inner surfaces or only the exterior. You can choose a versatile range of finishes like gloss, matte, embossing, debossing, and foil stamping to enhance visual appeal.

-

Internal Inserts and Accessories

To provide superior protection to inside-packed contents, the inside rigid boxes may have foam or custom die-cut inserts. Furthermore, you can make rigid boxes stylish by incorporating closures like magnetic, hinges, and drawer-style pulls to boost the unboxing experience.

Manufacturing Steps for Rigid Box Packaging

A step-by-step guide to the manufacturing process of rigid box packaging will help you simplify the overall process. Consider these steps to craft rigid boxes:

- Design and Pre-Press: In the initial step, define size, shape, and graphics. Or make two-dimensional and three-dimensional mockups.

- Cutting and Scoring: The rigid boxes are precisely cut to size. Then, their score lines are made to create foldable hinges.

- Folding and Assembling: The parts are folded if possible and then glued together. For rigid boxes, many parts are solid, so robust gluing and assembly are necessary.

- Wrapping and Finishing: Decorative paper or other materials are applied. Then, finishes are added. And inserts or other accessories are placed.

Explore Major Styles of Rigid Boxes

Rigid boxes come in many styles. Below are common styles with pros and cons, or what they are best suited for. Consider the popular styles for rigid boxes:

- Telescopic Lids: Provide good protection for your products with lid and base overlap. Exude a simple and clean look with telescopic styles.

- Shoulder Neck: Offers superior protection due to its layered design. A Shoulder Neck box provides a unique presentation with an exposed neck.

III.Hinged Lid: Open like a book with a lid attached on one side (hinged). Hinged boxes are good for presentation and luxury gift sets.

- Slide Out: Add unboxing thrill with a tray that slides out like a drawer, often with a ribbon pull. These slider boxes are great for layered products or sets. Sleeve and Tray: Cradle products like a baby with sleeve and tray boxes.

- These boxes have a fascinating mechanism where the outer sleeves slide over.

- Magnetic Closure: Create a premium feel with a click” feel as magnets embedded in flaps and base attract to each other in magnetic closure boxes.

Holiday Themed Rigid Boxes

Holiday-themed rigid boxes are sturdy packaging options, often custom-designed with festive patterns, colors, and logos for holidays like Christmas or Valentine's Day. The most common rigid boxes for holiday or specific events celebration are:

- Love Heart Lid-off Box

- Heart Shaped Box with Debossing

III.Christmas Tree Shaped Holiday Box

- Custom Printed Hexagon Shaped Box

- White Snowman Christmas Lid-off Box

- Hexagonal Hinged Box with Exterior Locking

What to Consider Before Choosing Rigid Boxes

If you are new to rigid boxes or want to choose rigid boxes for your product packaging, here are the key decision points to consider:

- Product Characteristics: Always keep in consideration size, weight, and fragility according to how much protection is required. And if your product is odd-shaped, then you might need custom inserts or custom-shaped rigid boxes.

- Budget Constraints: Understand per-unit cost vs batch size. For small runs, the costs of hard box packaging can be high. But in the case of larger runs, your unit cost gets reduced, but you need more upfront investment. Consider how much finishing detail, e.g., embossing, foil, and magnets, you want, since those factors also affect the cost.

- Brand Positioning: How much does the unboxing or packaging contribute to your perceived brand? The luxury market demands a premium feel, and premium rigid boxes can reposition your brand identity from ordinary to high-end.

- Logistics and Supply Chain: Do you have space for rigid boxes? Heavier and bulkier packaging leads to higher shipping costs. How long will your supplier take? What are the minimum order quantities?

- Material Choices: Can materials be recycled locally? Are coatings and adhesives certified or friendly to recycling? Using sustainable boards, water-based inks, and wrappers that are recyclable and biodegradable.

- Design and Aesthetics: Enhance the premium aesthetics of rigid boxes with finish types including gloss, matte, soft touch, and embossing. Examine high-resolution printing quality with color accuracy.

- Supplier and Manufacturer: Check the capability of your packaging suppliers. Whether they can work with the required finish. Do they have tools, including die-cutters and foiling? Always first get prototypes or a sample to check the feel, strength, and print. Also, consider lead times, minimum order quantity (MOQ), and turnaround time.

How to Design Rigid Boxes Effectively?

To design rigid boxes exquisitely, some practical tips for beginners are listed below. Ensure your rigid box does exactly what you want!

- Start with mock-ups or prototypes. Even mock the board and wrapping to test size plus usability.

- Keep in mind, a thick board takes up space, while dimensions may need slightly more clearance inside.

- Plan for insert design early, if needed, by adding foam, die-cut, velvet, or fabric lining.

- Be mindful of finishes that may increase cost significantly, such as foil stamping, debossing, and embossing etc.

- Think about how the box will be opened: magnetic closure, hinged lid, drawer, etc. The opening experience is part of unboxing.

- Design for print and graphics with enough bleed and safety margin. To choose the right color, consider the sample printed material if color matching matters.

- If you have multiple products and variants, keep some consistent elements in design so brand identity is unified.

Industrial Use Cases

Rigid boxes are popular for their diverse usage across multiple industries. Here are typical use cases tailored to various industries where rigid boxes are used and why.

- Jewelry: Items like rings and necklaces need protection; the rigid box is also part of the “gift” experience. Rigid jewelry boxes are usually used for packaging jewelry accessories.

- Cosmetics: Rigid boxes enhance visual appeal and highlight your brand image for items like perfumes, lip gloss, makeup kits, and moisturizers.

- Electronics: Protect phones and tech accessories during transport and fulfil “premium tech packaging” expectations of customers.

- Gift packaging: Experience and presentation matter, and the rigid box itself becomes part of the gift value.

- Board Games: Large flat rigid boxes help keep components safe with a durable construction that keeps boards safe against knocks and bumps during shipping.

Cost Factors and Typical Pricing

Understanding what factors most affect cost helps you decide trade-offs for rigid box packaging. Consider the following elements:

- Material Thickness & Quality: The thicker the material, the higher the grade board, which leads to more cost.

- Finish & Decoration: Using decorative finishes like foil stamping, embossing, special papers, soft touch coatings, etc, costs more.

- Complexity of Design: Custom shapes, inserts, windows, and magnetic closures require more labor, tools, and production steps. It eventually increases manufacturing costs.

- Production volume: Larger orders on rigid boxes lower per-unit cost. However, if you purchase small batches, they cost you more per box.

- Location and Shipping: The cost of shipping materials from the supplier, shipping the final product to you, also affects costs. If shipping internationally, your business might encounter add-ons in the form of excise duties, etc.

- Waste and Efficiency: Better layout, proper cutting patterns, and fewer errors during the manufacturing of a rigid box save money.

Brand That Gained Prestige with Rigid Boxes

Here is a case study of “Lindt Chocolate,” a confectionery brand. Lindt wanted to pack 27 classic milk chocolate bars in a “super-sized” rigid box for a special promotional seasonal release. They needed packaging that conveys luxury, delivers protection, but also handles storage and shipping constraints since super-sized rigid boxes are bulky.

So, Lindt chose a collapsible rigid box to manage storage and logistical challenges. The chosen box can be shipped and stored flat, then assembled rigidly. This resolves the problem of reducing space cost. As a result, Lindt’s campaign gets attention partly because of its premium rigid packaging.

Future Trends in Luxury Rigid Packaging

Future trends in luxury rigid packaging emphasize using eco-friendly materials like paperboard and plant-based foils. Instead of sharp color usage and maximalist design, brands are more likely to focus on minimalist design with calm palettes and understated elegance.

In the near future, you will witness the integration of smart packaging features like QR codes and NFC chips in rigid boxes to make an unboxing experience “digital.”

Conclusion

Since you have explored everything in detail, from material, manufacturing process, styles, and types to real-world examples of rigid boxes. Hopefully, you will be able to make a well-informed decision when buying custom rigid boxes for your high-end products.

Now, if you are interested in finding a reliable supplier for rigid packaging, contact Custom Boxes Lane.

The material used for rigid box packaging is either greyboard, chipboard, or paperboard. However, you can use satin-lined or textured paper for wrapping outside of the box.

To use custom rigid boxes with a logo, leverage finishes like embossing, debossing, or foil stamping to highlight your brand details in a competitive market.

You can use rigid boxes for shipping because they are super sturdy to resist knocks and bumps during shipping while cradling the contents.

You can get custom rigid boxes wholesale from online wholesalers or local vendors. Contact Custom Boxes Lane to get premium quality rigid boxes at wholesale rates without compromising on quality.